The full flow metalworking fluid vacuum filter FV and FVC are a cost efficient and versatile filters for removing solid particles from metalworking fluids such as emulsion/oils or similar applications like parts washing. The coolant filter can be equipped with disposable media and a permanent belt to reduce disposal cost. Continuous operation is guaranteed by using a clean tank during the index cycle which is a fully automated action.

Main features of the vaccuum coolant filter:

- low maintenance and low complexity

- low energy – the filter pump is system pump

- low disposal costs with permanent belt media

- high flow rates

- increased filtration quality

- small foot print

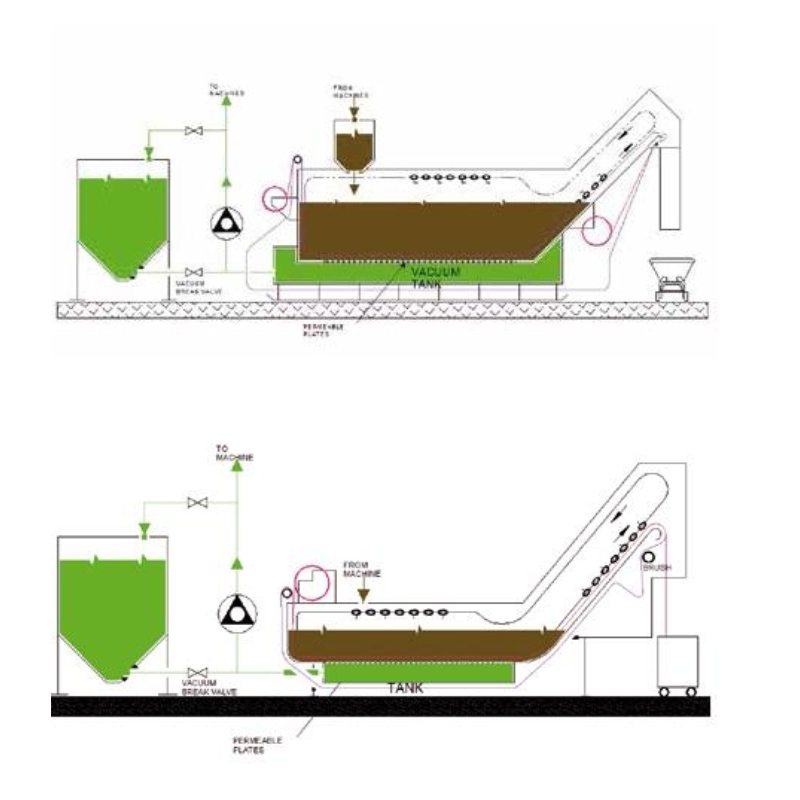

FV full flow coolant vaccum filter

Design

The vacuum filter is a cost efficient and versatile filter for removing solid particles from metalworking fluids (emulsion or oil) or similar applications like parts washing. The filter pump creates a 0.3 bar differential pressure across the filter media so that flow rate and filtration quality exceed by far the gravity type filters. The filter may be equipped with disposable media and/or a permanent belt to reduce disposal cost. Continuous operation is guaranteed by using a clean tank during the index cycle which is a fully automated action.

Main features of the coolant recovery filter:

- low maintenance / low complexity

- low energy (filter pump is system pump)

- low disposal costs (permanent belt media)

- high flow rates

- increased filtration quality

- small foot print

Function

Contaminated liquid discharges from the machine tool into the filter tank where swarf settles out.

The bottom of the filter tank is separated from the vacuum tank by means of rigid permeable panels. A flight bar conveyor is installed on top of the panels. The filter media moves between the panels and the flight bar conveyor. The filter/system pump creates a vacuum and forces the liquid through the filter media into the vacuum tank. Clean liquid is supplied from the vacuum tank to the machines and the clean tank.

Due to the build-up of collected solids on the filter media (filter cake) the vacuum will increase and an automated index cycle will be initiated as soon as a predefined vacuum has been reached.

During the index the vacuum break valves opens and the conveyor moves both the filter media and the collected swarf to the filter discharge. To ensure a continuous flow to the machine tool clean liquid is taken from the clean tank until the vacuum break valves closes at the end of the index cycle.

If a permanent belt is used as filter media, the belt will be back flushed during the index cycle

FVC full flow coolant vacuum filter

Design

The compact vacuum coolant filter FVC is a cost efficient and versatile filter for removing solid particles from metalworking fluids (emulsion or oil) or similar applications like parts washing. The filter pump creates a 0.3 bar differential pressure across the filter media so that flow rate and filtration quality exceed by far the gravity type filters.

The FVC range has been designed to meet the requirements for single machine solutions in a cost effective way.

The coolant filter may be equipped with disposable media and/or a permanent belt to reduce disposal cost. Continuous operation is guaranteed by using a clean tank during the index cycle which is a fully automated action.

Main features of the coolant filter:

- low maintenance / low complexity

- low energy (filter pump is system pump)

- low disposal costs (permanent belt media)

- high flow rates

- increased filtration quality

- small foot print

TECHNICAL DATA

Function

Contaminated liquid discharges from the machine tool into the filter tank where swarf settles out.

The bottom of the filter tank is separated from the vacuum tank by means of rigid permeable panels. A flight bar conveyor is installed on top of the panels. The filter media moves between the panels and the flight bar conveyor. The filter/system pump creates a vacuum and forces the liquid through the filter media into the vacuum tank. Clean liquid is supplied from the vacuum tank to the machines and the clean tank.

Due to the build-up of collected solids on the filter media (filter cake) the vacuum will increase and an automated index cycle will be initiated as soon as a predefined vacuum has been reached. During the index the vacuum break valves opens and the conveyor moves both the filter media and the collected swarf to the filter discharge. To ensure a continuous flow to the machine tool clean liquid is taken from the clean tank until the vacuum break valves closes at the end of the index cycle. If a permanent belt is used as filter media, the belt will be brushed and back flushed during the index cycle.

- The full flow metalworking fluid vacuum filter FV and FVC are a cost efficient and versatile filters for removing solid particles from metalworking fluids such as emulsion/oils or similar applications like parts washing. The coolant filter can be equipped with disposable media and a permanent belt to reduce disposal cost. Continuous operation is guaranteed by using a clean tank during the index cycle which is a fully automated action. Main features of the vaccuum coolant filter: •low maintenance and low complexity •low energy – the filter pump is system pump •low disposal costs with permanent belt media •high flow rates •increased filtration quality •small foot print FV full flow coolant vaccum filter Design The vacuum filter is a cost efficient and versatile filter for removing solid particles from metalworking fluids (emulsion or oil) or similar applications like parts washing. The filter pump creates a 0.3 bar differential pressure across the filter media so that flow rate and filtration quality exceed by far the gravity type filters. The filter may be equipped with disposable media and/or a permanent belt to reduce disposal cost. Continuous operation is guaranteed by using a clean tank during the index cycle which is a fully automated action. Main features of the coolant recovery filter: •low maintenance / low complexity •low energy (filter pump is system pump) •low disposal costs (permanent belt media) •high flow rates •increased filtration quality •small foot print Function Contaminated liquid discharges from the machine tool into the filter tank where swarf settles out. The bottom of the filter tank is separated from the vacuum tank by means of rigid permeable panels. A flight bar conveyor is installed on top of the panels. The filter media moves between the panels and the flight bar conveyor. The filter/system pump creates a vacuum and forces the liquid through the filter media into the vacuum tank. Clean liquid is supplied from the vacuum tank to the machines and the clean tank. Due to the build-up of collected solids on the filter media (filter cake) the vacuum will increase and an automated index cycle will be initiated as soon as a predefined vacuum has been reached. During the index the vacuum break valves opens and the conveyor moves both the filter media and the collected swarf to the filter discharge. To ensure a continuous flow to the machine tool clean liquid is taken from the clean tank until the vacuum break valves closes at the end of the index cycle. If a permanent belt is used as filter media, the belt will be back flushed during the index cycle FVC full flow coolant vacuum filter Design The compact vacuum coolant filter FVC is a cost efficient and versatile filter for removing solid particles from metalworking fluids (emulsion or oil) or similar applications like parts washing. The filter pump creates a 0.3 bar differential pressure across the filter media so that flow rate and filtration quality exceed by far the gravity type filters. The FVC range has been designed to meet the requirements for single machine solutions in a cost effective way. The coolant filter may be equipped with disposable media and/or a permanent belt to reduce disposal cost. Continuous operation is guaranteed by using a clean tank during the index cycle which is a fully automated action. Main features of the coolant filter: •low maintenance / low complexity •low energy (filter pump is system pump) •low disposal costs (permanent belt media) •high flow rates •increased filtration quality •small foot print Function Contaminated liquid discharges from the machine tool into the filter tank where swarf settles out. The bottom of the filter tank is separated from the vacuum tank by means of rigid permeable panels. A flight bar conveyor is installed on top of the panels. The filter media moves between the panels and the flight bar conveyor. The filter/system pump creates a vacuum and forces the liquid through the filter media into the vacuum tank. Clean liquid is supplied from the vacuum tank to the machines and the clean tank. Due to the build-up of collected solids on the filter media (filter cake) the vacuum will increase and an automated index cycle will be initiated as soon as a predefined vacuum has been reached. During the index the vacuum break valves opens and the conveyor moves both the filter media and the collected swarf to the filter discharge. To ensure a continuous flow to the machine tool clean liquid is taken from the clean tank until the vacuum break valves closes at the end of the index cycle. If a permanent belt is used as filter media, the belt will be brushed and back flushed during the index cycle.

DOWNLOAD

Download Leaflet – Click Here